The windshield molding, vital for both car structure and aesthetics, is susceptible to damage from weather, road hazards, and accidents. Skilled technicians in collision centers perform precise replacements, ensuring driver safety and restoring visual appeal. Modern molding components offer improved performance and durability compared to older parts, enhancing fuel efficiency and resistance to corrosion. Eco-friendly manufacturing techniques reduce waste and harmful chemical usage, while cost-effectiveness due to lower maintenance requirements makes windshield molding replacement a sensible solution for manufacturers and environmentally conscious consumers.

In today’s automotive landscape, understanding the benefits of updated molding components is crucial. Windshield molding replacement isn’t just about aesthetics; it’s a vital safety measure that enhances structural integrity. Modern molding components offer improved performance and durability, ensuring your vehicle stands up to the rigors of daily driving. Moreover, these updates have a positive environmental impact and can be cost-effective in the long run. This article explores why windshield molding replacement is a game-changer for both safety and style.

- Why Windshield Molding Replacement is Essential for Safety and Aesthetics

- Improved Performance and Durability: The Advantages of Modern Molding Components

- Environmental Impact and Cost-Effectiveness in Windshield Molding Updates

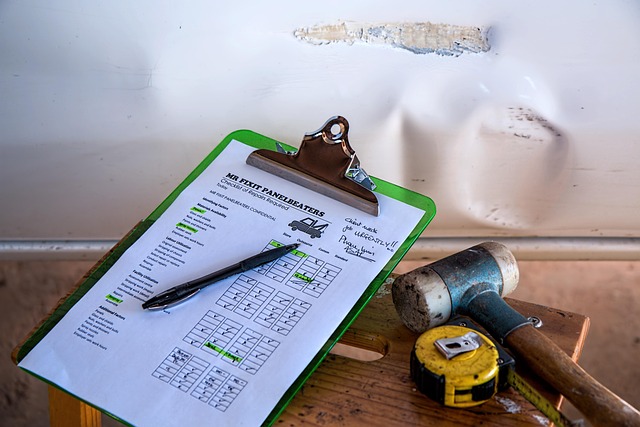

Why Windshield Molding Replacement is Essential for Safety and Aesthetics

The windshield molding, a crucial component of your vehicle’s exterior, plays a significant role in both safety and aesthetics. Its primary function is to secure and seal the windshield, ensuring it stays firmly in place during travel. Over time, this molding can become damaged or deteriorated due to various factors such as weather conditions, road debris, and accidents. Windshield molding replacement is not just about enhancing the look of your car; it’s a vital safety measure. A cracked or broken molding can compromise the integrity of the windshield bond, potentially leading to hazards during a collision.

When considering auto body work, especially after a collision, focusing on windshield molding replacement is essential. Skilled technicians in collision centers are adept at handling this task, ensuring precise frame straightening and meticulous repairs. By replacing the molding, they not only restore the vehicle’s structural integrity but also revive its visual appeal, making it look like new again. This attention to detail contributes to a satisfying driving experience, knowing your safety is optimized while you navigate the hustle and bustle of daily commutes.

Improved Performance and Durability: The Advantages of Modern Molding Components

Modern molding components offer significant advantages when it comes to performance and durability, especially when compared to older parts. One of the key benefits is their enhanced structural integrity. With advancements in manufacturing techniques, these new components are designed to withstand extreme conditions, ensuring longer lifespans for various automotive parts, including windshield molding replacement. Their improved strength-to-weight ratio makes them lighter alternatives, which can contribute to better fuel efficiency and overall vehicle performance.

Additionally, the latest molding technologies involve the use of advanced materials that provide superior resistance to corrosion and environmental factors. This is particularly important for car body repair and auto body shops as it reduces the need for frequent replacements due to damage caused by elements like UV radiation or extreme temperatures. Modern components can maintain their structural integrity over time, ensuring a more seamless and efficient car body repair process.

Environmental Impact and Cost-Effectiveness in Windshield Molding Updates

The environmental impact of manufacturing processes is a growing concern for many industries, and the automotive sector is no exception. Windshield molding updates offer an eco-friendly alternative by reducing waste and minimizing the use of harmful chemicals. Traditional molding methods often rely on petroleum-based materials and energy-intensive production techniques, contributing to carbon footprints. However, updated components utilize sustainable resources and more efficient manufacturing processes. This shift towards greener practices not only benefits the planet but also car dent repair enthusiasts who prioritize environmental consciousness.

Moreover, cost-effectiveness is a key advantage of implementing newer windshield molding designs. While initial investment in updated equipment and materials may be higher, long-term savings are significant. Modern molds often require less maintenance, leading to reduced downtime for vehicle body shops. Additionally, the improved durability of new molding components can decrease the frequency of replacements, further lowering costs. These benefits make windshield molding replacement a smart financial decision for both automotive manufacturers and consumers concerned about the environment and their wallets.

In conclusion, updating windshield molding components offers a multitude of benefits, from enhanced safety and aesthetic appeal to improved performance and durability. The environmental impact and cost-effectiveness of these upgrades make windshield molding replacement a smart choice for both vehicle owners and manufacturers alike. By keeping up with modern molding components, we can ensure safer, more efficient, and eco-friendly vehicles for the future.